Slackline webbing can be damaged from any number of ways. It is important to understand the impact that damage may have the strength of the webbing. Does one cut thread cause the webbing to be compromised?

Hypothesis:

The strength comes from the weave and the strands in the webbing. Minor damage with nearly 100% of the threads and weave still intact, the strength should not be significantly affected. Major damage to the webbing such as cut threads of broke weave will significantly compromise the strength.

Materials:

- 4 x 3m pieces of Skypilot Nylon Webbing

- 4 x 3 1/4 T 5/8″ Steel Shackle

- Certified Break Test Machine

Procedure:

Break test Method – Secure the webbing to be tested using the Static Lock Method below. A constantly increasing force will be applied at roughly 2500lbs/minute until the webbing fails.

Static Lock Method – Double Wrapped Lock off using 2 rated shackles. The same method was used on both ends of the webbing in every test

Test #1 – Control Test – Performed a break test of an undamaged piece of webbing to establish a control point.

Test #2 – Minor Damage Test – Repeat the test with a piece of webbing that was damaged by pulling some threads out using Velcro.

Test #3 – Major Damage – Repeat the test with a piece of webbing cut 1/5 of the width of the webbing using a knife

Test #4 – Extreme Damage – Repeat the test with a piece of webbing cut 1/3 of the width of the webbing using a knife

Test 3 – Major Damage

Test 4 – Extreme Damage

Test 4 – Extreme Damage

Data Collection:

Test Results

| TEST | BREAKING POINT |

|---|---|

| Test 1 – Control | 22.2 kN (5000 lbs) |

| Test 2 – Minor Damage | 22.4 kN (5050 lbs) |

| Test 3 – Major Damage | 16.2 kN (3650 lbs) |

| Test 4 – Extreme Damage | 14.7 kN (3300 lbs) |

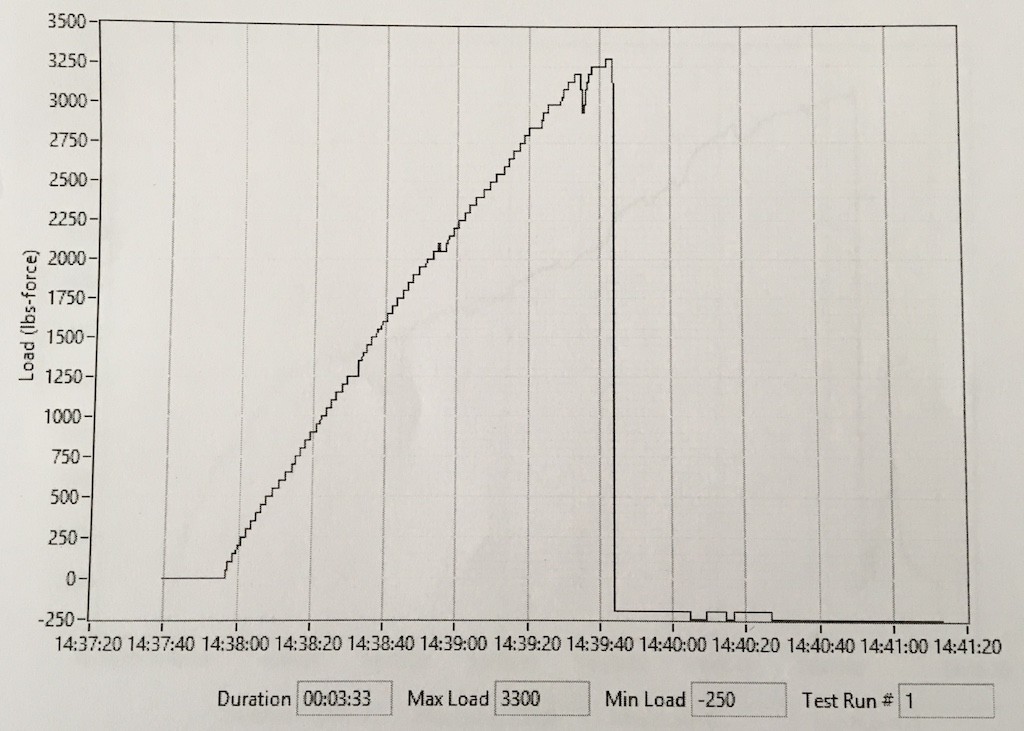

Extreme Damage Break Test Read-out

Analysis:

Control Test – As expected the ‘control tests’ webbing broke inside the double wrapped static locker at about 80% of the webbing MBS.

Minor Damage Test – With all the webbing strands still intact, the minorly damaged webbing broke inside the double wrap static locker well away from the damaged section. There seems to be no significant decrease in webbing strength when compared to the control test.

Major Damage Test – With roughly 1/5 of the webbing strands severed, the webbing broke at the damaged point at 60% of the webbing MBS and roughly 70% of the control test break loads. The damaged webbing remained in good condition up to the point when it broke.

Extreme Damage Test – With roughly 1/3 of the webbing strands severed, the webbing broke at the damaged point at 53% of the webbing MBS and roughly 64% of the control test break loads. The damaged webbing remained in good condition up to the point when it broke.

Conclusion:

Minor damage to slackline webbing does not appear to significantly reduce its strength. With webbing is good condition, it is more likely to break inside the static locker than at some point in the middle of the webbing.

As Expected more serious damage to webbing does dramatically reduce its strength. It was surprising that even with an extreme cut in the webbing, it still held loads exceeding 12kN, which in a normal situation, should be far above any force applied to the system.

Only a single test of each variation was performed. Additional tests are required to better understand the impact of damage on slackline webbing. Webbing should be inspected prior to every use and retired if any major damage is discovered. Never use damaged gear or equipment because it is not possible to predict how it might perform.

Leave A Comment

You must be logged in to post a comment.